Founded in 1954, Lagarde are world leaders in the manufacture of autoclaves (retorts) and are based just south of Montelimar in Southern France.

Most of the world’s leading producers of ambient foods and Europe’s fast-moving recipe dish manufacturers rely on Lagarde technology to make appetising and safe food products.

Lagarde’s product range includes rotating, static and rocking retorts with diameters from 600 to 2500mm and from 1 to 8 baskets in capacity. In addition, Lagarde manufacture pilot retorts for product developers and process establishment.

The updated PC control system, Samantha™, is a touch screen HMI that gives accurate temperature and pressure control in real time to within 0.1°C and 15 mbar respectively, ideal for the new wave of plastic and flexible containers, such as Doypacks – on which Lagarde lead both the human and pet food markets.

Lagarde are able to offer steam/air, raining water, steam spray and full water immersion retorts of all sizes. Each process has its advantages, to ensure all types of products and containers are perfectly processed.

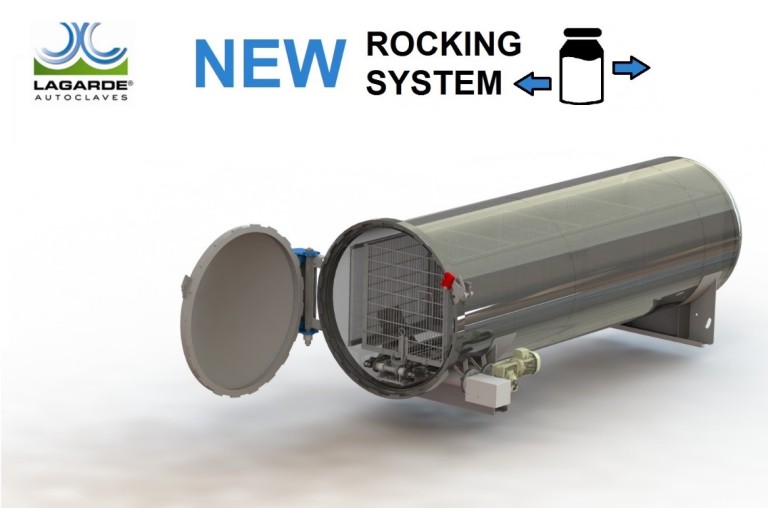

The latest technology from Lagarde is the first steam and air retort Rocking System®. This is an exclusive application that uses the basket’s loading and unloading system to agitate the product load, whilst sterilisation or pasteurisation takes place.

The benefit of a rocking machine is particularly seen with milk applications, as this reduces the challenges of the Maillard effect – a non-enzymatic reaction between sugars and proteins that occurs upon heating, that causes the product to caramelise/brown.

Machine configurations are available in 1- 4 baskets and the system is easily adapted for all container types. It is most efficient with high viscosity products such as soups, sauces and cream dishes.

Full test facilities are available at Lagarde's state-of-the-art sustainable factory.

Rocking Retort Video